Technology

The sky-rocketing demand of the digital data streams in this decade drives the datacenter owners, cloud service providers and mobile telecommunication operators into an ever-lasting war against the bandwidth shortage and latency. The accelerating evolutions of the high speed interconnect play essential roles in the linkages from network to network archetecture. This dynamic and fast growing interconnect market provides innovation opportunities for new technologies that may transpose the conventional wisdoms of optical transceivers.

As an innovative entrant, Centera Photonics dedicates itself on developing the photonic integration of the interconnect through semiconductor material and processes. We integrate the optical and electrical devices for optical interconnect on a petite silicon chip which is manufactured by means of semiconductor MEMS (Micro-Electro-Mechanical System) process.

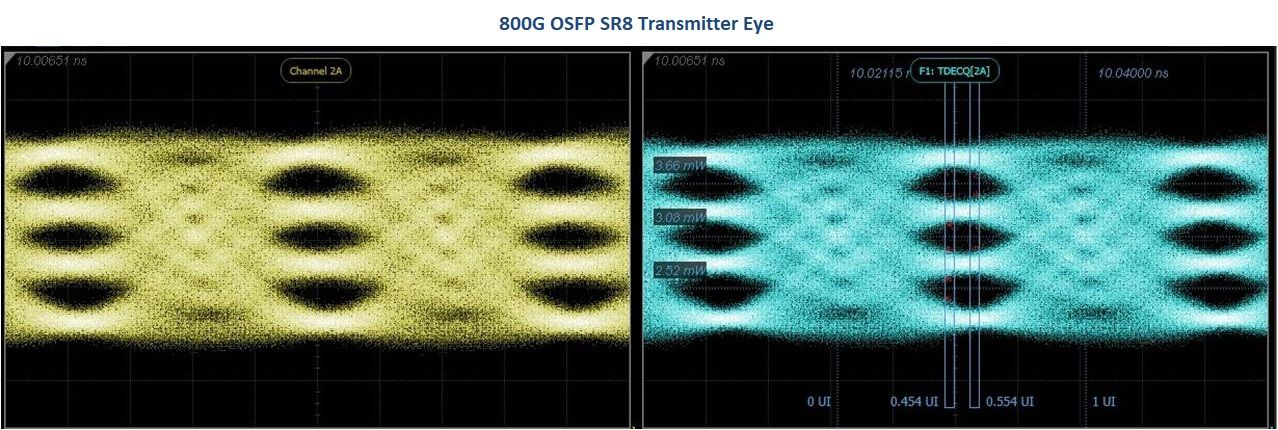

The sophisticated O/E engine platform revolutionizes the industry in two aspects : the miniatuation in size and the ease of manufacturing versus the tradidtional optical assemblies. This platform has been demonstrated that can support optical interconnect roadmap from 100G, 200G, 400G and beyond.

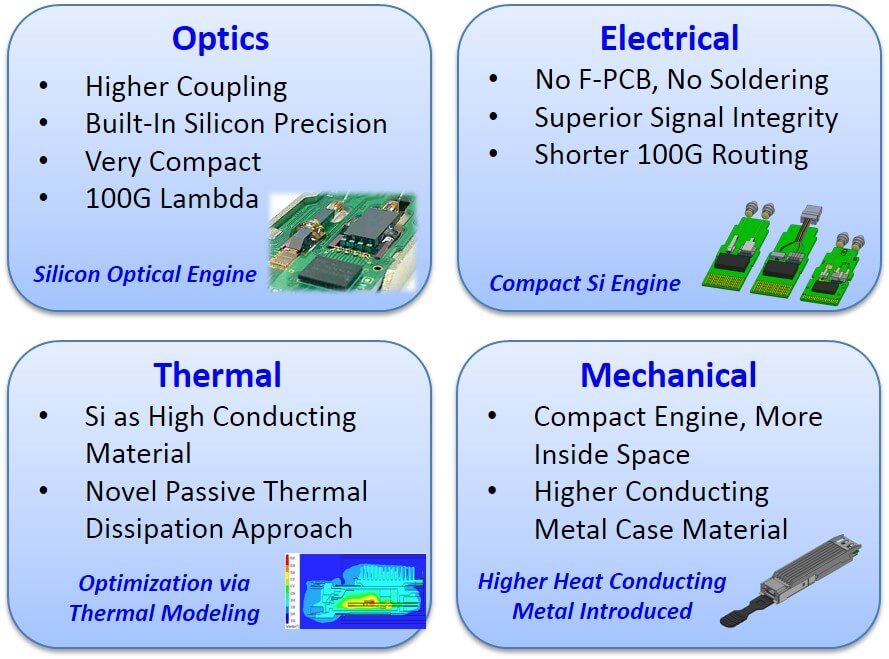

The Features of the Optical-Electrical Engine

- Mature, reliable and high accuracy semiconductor process

- Passive optical alignment; no lens needed

- Easy assembly : high yield expected

- Small form factor; fit any type connectors, board mount available

Centera’s Core Technologies

- Optical-Electrical System Design

- Semiconductor MEMS Technology for Optical Interconnects

- Photonic System Integration (Opto-Electrical SIP)

The optical-electrical platform also offers a gateway on migration of optical interconnect to next generation I/O requirement of super-high performance silicon PICs (photonic ICs).

Optical-Electrical System Design

System Design has two major categories and is implemented by in-house design team. Optical crosstalk and electrical interferences introduced from parallel optical structure are minimized, specially under small dimensional constraints.

Coupling efficiency of optical components to fibers have also been investigated to meet design goals and tolerance for volume production. The system designs effectively surpass the challenges from multi-channel system with high data rates. Process design rules are defined for yield and tolerance considerations.

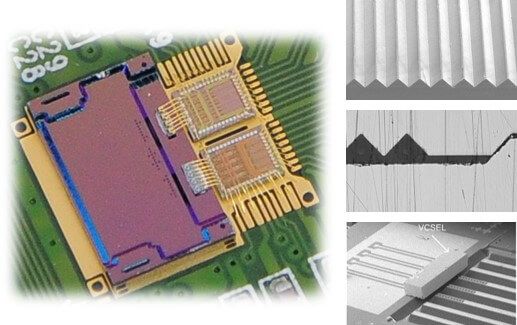

Semiconductor MEMS Processed Silicon Optical Engines

The optical engine from system design phase will be processed in a semiconductor foundry fab. The process monolithically builds highly integrated optical elements and electrical circuits on silicon wafers with high precision at competitive cost.

Below listed are some elements achieved by lithography, etching, metal plating and sputtering processes.

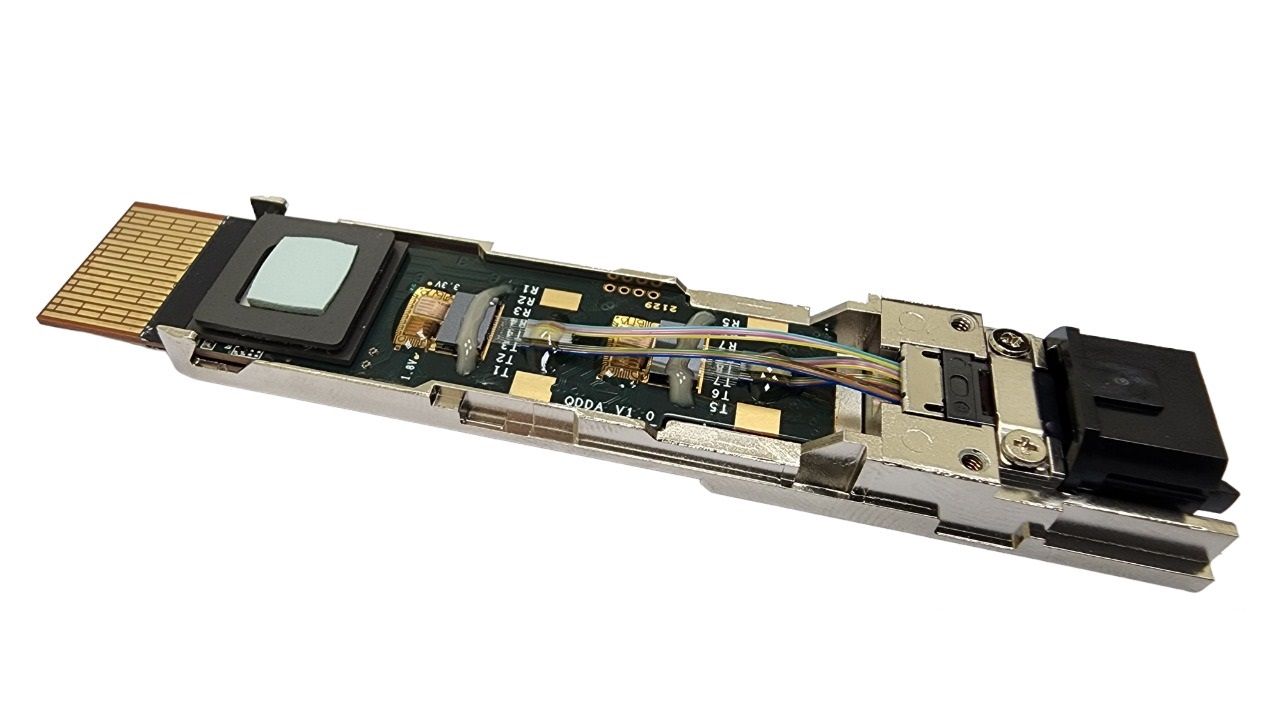

The solution is made possible via smart mechanism designs and high precision assemblies of optical components (VCSEL/PD), driver IC, Transimpedance Amplifier (TIA), controller, passive components and optical fibers.

The SIP can be part of the whole transceiver module otherwise it can be tailored to fit the requirement of different applications, including enterprise-use QSFP/OSFP transceiver, AOC, OBO (on board optics) or consumer applications like Thunderbolts, TV Links and mobile devices.

High Yield/Easy Assembly Optical Transceivers

The assembly processes of Optical Transceivers are developed by Centera’s experienced engineering team. The fundamental idea behind is “DFM, Design for Manufacturing”. The ultimate goal is to make the transceiver assembly as easy as IC packaging. Some of the toolings and equipment were developed by Centera’s engineering team to fit the special mechnism of MEMS optical engines, such as passive optical coupling.

The in-house production lines are fully automatic and highly scalable to various products. The fabrication process is under close monitoring and control by Centera’s operation team. Centera guarentees high yield, cost effective transciever manufacuring to its customers.